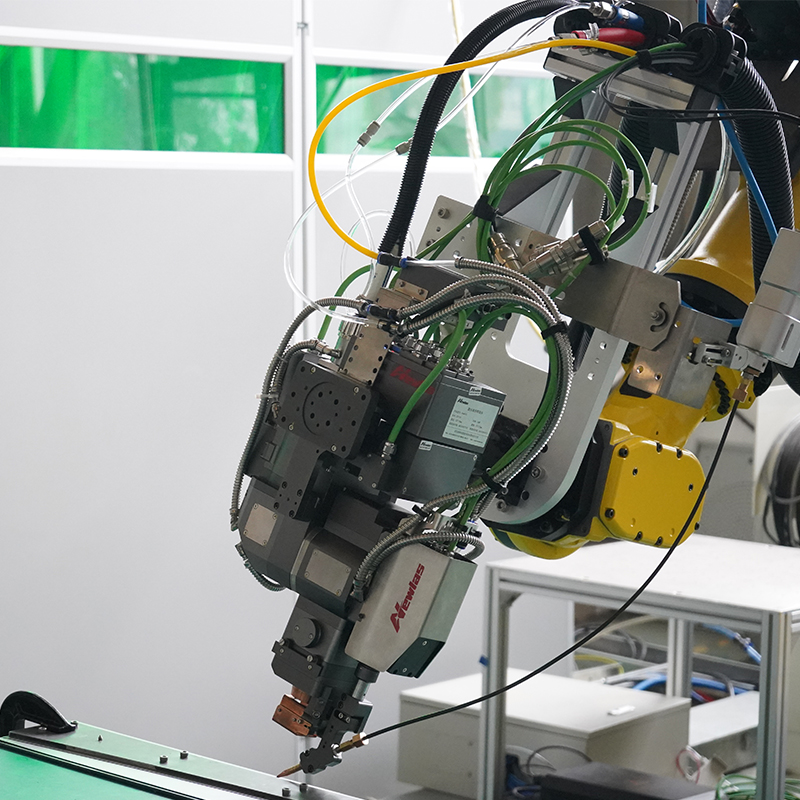

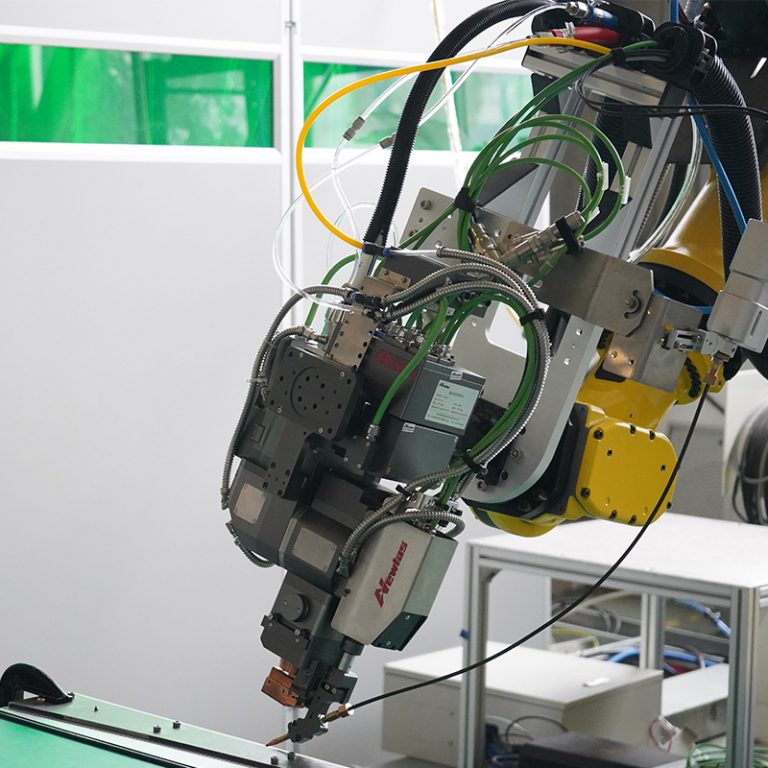

Newlaz laser brazig welding subsystem has high-precision welding seam tracking and automatic focus compensation functions, which can realize brazing, fusion welding, filler wire welding, etc.; it has high stability and is suitable for long welding seams.

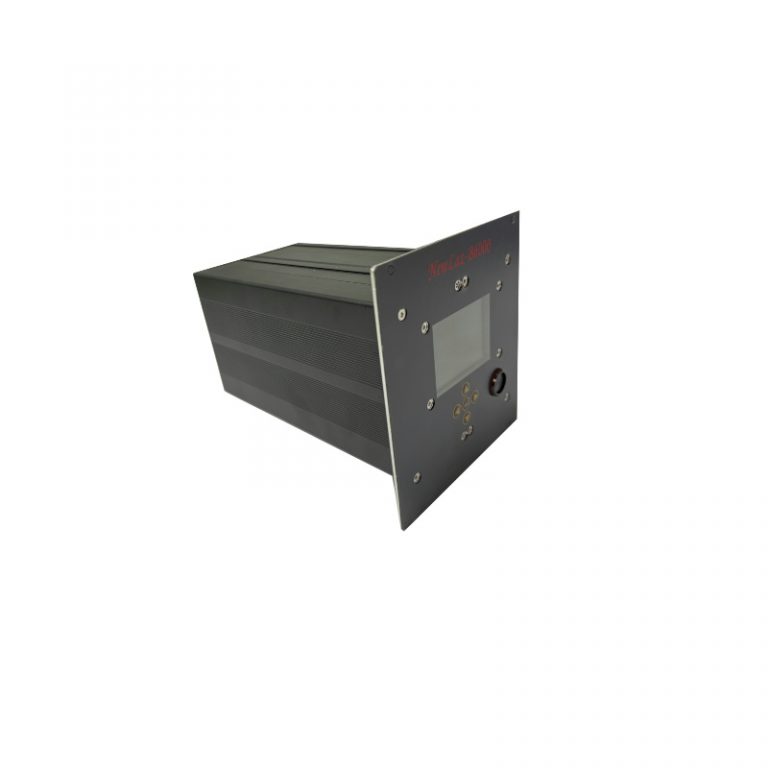

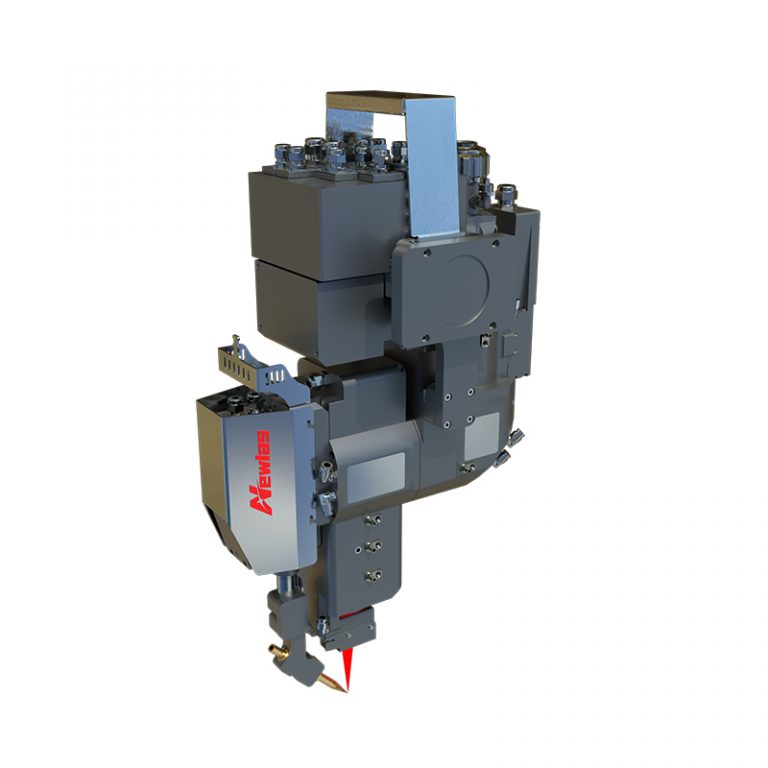

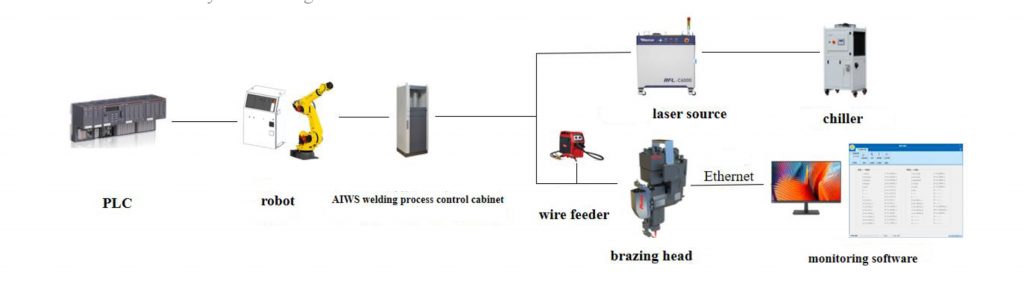

System Configuration

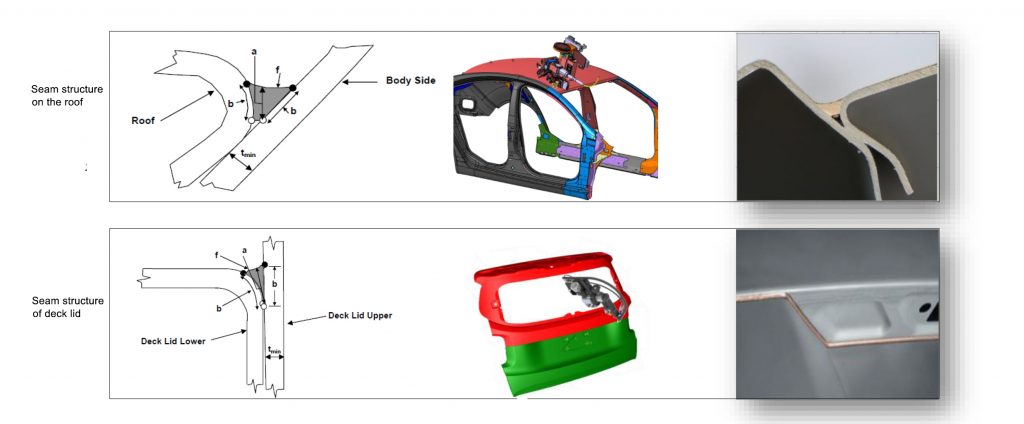

Application

Advantages

- Welding wire guide tracking: the welding wire tactile sensor accurately controls the tracking force, automatically compensates for the deviation of the part, and realizes the stability of the welding process;

- Automatic focusing: the welding wire can follow the seam up and down, and the focus is automatically adjusted to ensure that the spot size on the welding wire is constant;

- Easy integration: fast integration with external systems such as wire feeding systems, lasers source, camera displays;

- Modular design: at the same time, FA3 brazing head have functional ductility, suitable for any type of laser source, and easy to maintain and expand;

- User-friendly: it can be seamlessly replaced withequipment from European and American area, and is compatible with existing laser brazing and fusion welding systems, with short debugging cycle and strong stability.